The process of removing the clutch release fork on a VAZ 2110 car and its maintenance, if necessary, replacement and reassembly of parts. The process of removing the clutch release fork on a VAZ 2110 car and its maintenance, if necessary, replacement and reassembly of parts.

Over time, the operation of the car also lends itself to wear in the gearbox - the clutch release fork. Despite the roughness of the metal and the simplicity of the part, some elements can still be deformed or erased, which requires timely replacement. If the time has come to replace it with a new one, then it will not hurt to completely disassemble the gearbox and inspect it, if necessary, repair it, because without removing the gearbox you cannot reach the clutch release fork.

We were replacing a part on a VAZ 2110 car.

Procedure for removing and replacing the clutch release fork:

1. First, after removing the gearbox, remove the clutch release bearing.

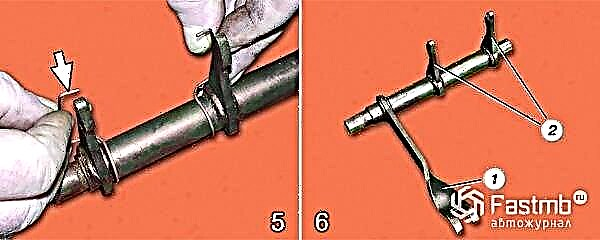

2. The next step is to remove the rubber boot (number 1). You need to pry it off with a screwdriver and pull it off the clutch release fork (number 2 in the photo). If the protective rubber cover is defective (cracked, deformed, no elasticity), then replace it with a new one. 3. Using a screwdriver, pry the plastic bushing of the fork axle, and with pliers on the inside of the clutch housing, squeeze the tabs that fix it and remove this bushing. If this plastic cap is defective (no petals, cracks or other obvious signs of wear), replace it with a new one.

4. Now it comes to removing the clutch release fork. Lift it up and remove its axle from the bushing, which is pressed into the clutch housing and dismantle the fork, removing the axle, and then the lever from the holes in the clutch housing.

5. Squeeze the ends of the fork latch and pull out. If the retainer has defects (no elasticity or even broken), then replace it with a new one.

6. The plug that is responsible for disconnecting the drive must be replaced with a new one if it has:

- 1 - the fork arm is cracked, bent or deformed;

- 2 - the legs of the part in the area where they contact the bearing sleeve also have obvious defects and signs of wear.

7. Inspect the yellow metal bushing; if it has defects, press it in and insert a new one as far as it will go.

8. Before reinstalling the drive cut-off plug - lubricate both bushings (metal and plastic) with grease.

9. Now you can safely mount the clutch release fork back in the dismantling procedure. But, pay special attention to the protrusion on the plastic bushing, it should fall into a pothole on the clutch housing, and its petals should tightly fix the bushing in the crankcase from falling out.